Cleanroom standards ensure generic drugs are safe and effective by controlling airborne particles, microbes, and environmental conditions. Learn how ISO grades, FDA/EU rules, and human factors impact quality - and why compliance isn't optional.

Pharmaceutical Cleanrooms: Standards, Requirements, and Why They Matter

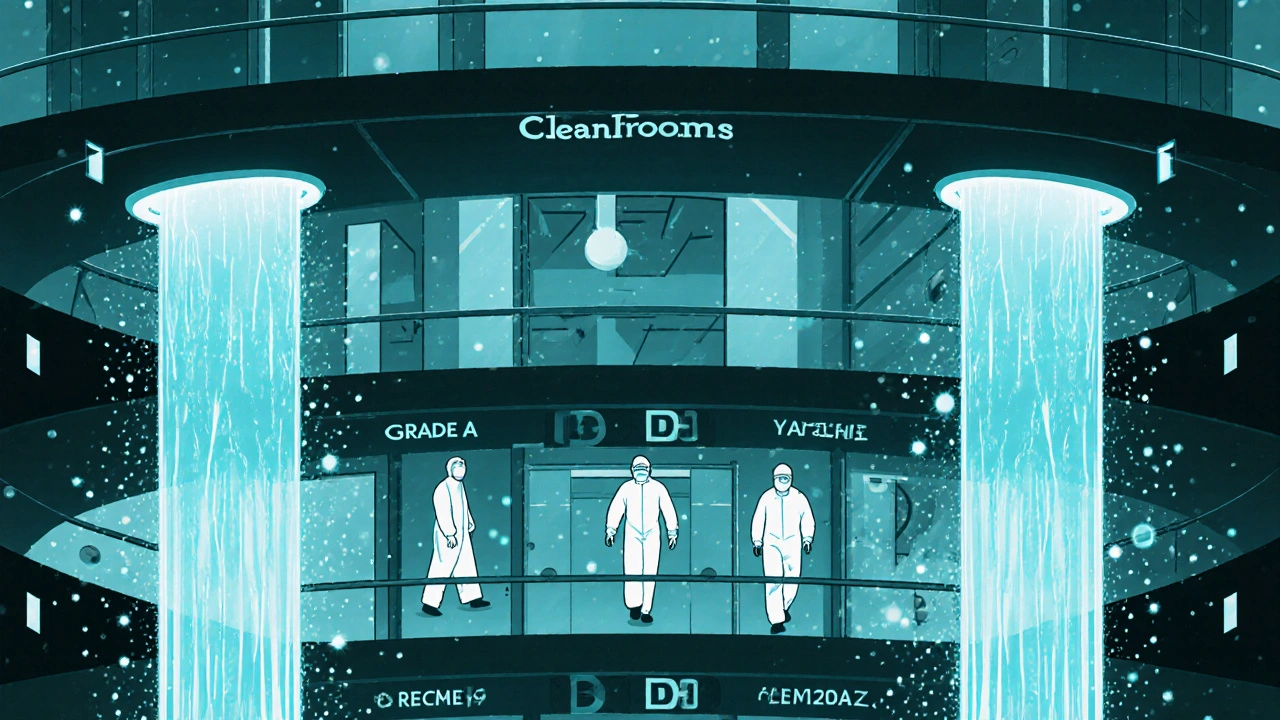

When you take a pill or get an injection, you expect it to be safe—no dust, no bacteria, no hidden contaminants. That’s where pharmaceutical cleanrooms, controlled environments designed to minimize airborne particles and microbial contamination during drug manufacturing. Also known as GMP cleanrooms, they’re not just rooms—they’re the foundation of every sterile medication you use. Without them, even the most powerful drug could make you sick instead of heal you.

These cleanrooms aren’t just about air filters. They follow strict rules from agencies like the FDA and EMA, and they’re built around contamination control, the system of protocols, materials, and procedures that keep microbes and particles out of drug products. Think of it like a hospital operating room, but for pills, eye drops, and IV bags. Every surface, every tool, every person entering must follow rules: special gowns, air showers, controlled airflow, and zero tolerance for mess. Even a single human hair can trigger a batch recall.

It’s not just about cleanliness—it’s about consistency. A cleanroom in India must meet the same standards as one in Germany or Texas. That’s why cleanroom standards, specific technical benchmarks for particle counts, humidity, pressure, and airflow rates in pharmaceutical environments are written in hard numbers: ISO 14644-1, EU GMP Annex 1, and FDA guidance documents. These aren’t suggestions—they’re legal requirements. A single violation can shut down a factory for months. And it’s not just big pharma: even small labs making custom compounded drugs need these controls.

Behind every cleanroom are people trained to move slowly, speak softly, and avoid touching anything unnecessary. The air inside? It’s filtered dozens of times per hour. The floors? Non-shedding epoxy. The doors? Sealed to keep pressure differential locked in. These aren’t fancy gadgets—they’re basic, non-negotiable tools. And the stakes? High. One contaminated vial of insulin or antibiotic could kill someone.

What you’ll find below isn’t theory. It’s real-world insight from posts that dig into how cleanrooms are built, monitored, and audited. You’ll see how manufacturing changes trigger regulatory reviews, why even tiny shifts in airflow can ruin a batch, and how companies stay compliant without going broke. Whether you work in pharma, manage a lab, or just want to know why your medicine is safe, this collection gives you the facts—no fluff, no jargon, just what matters.