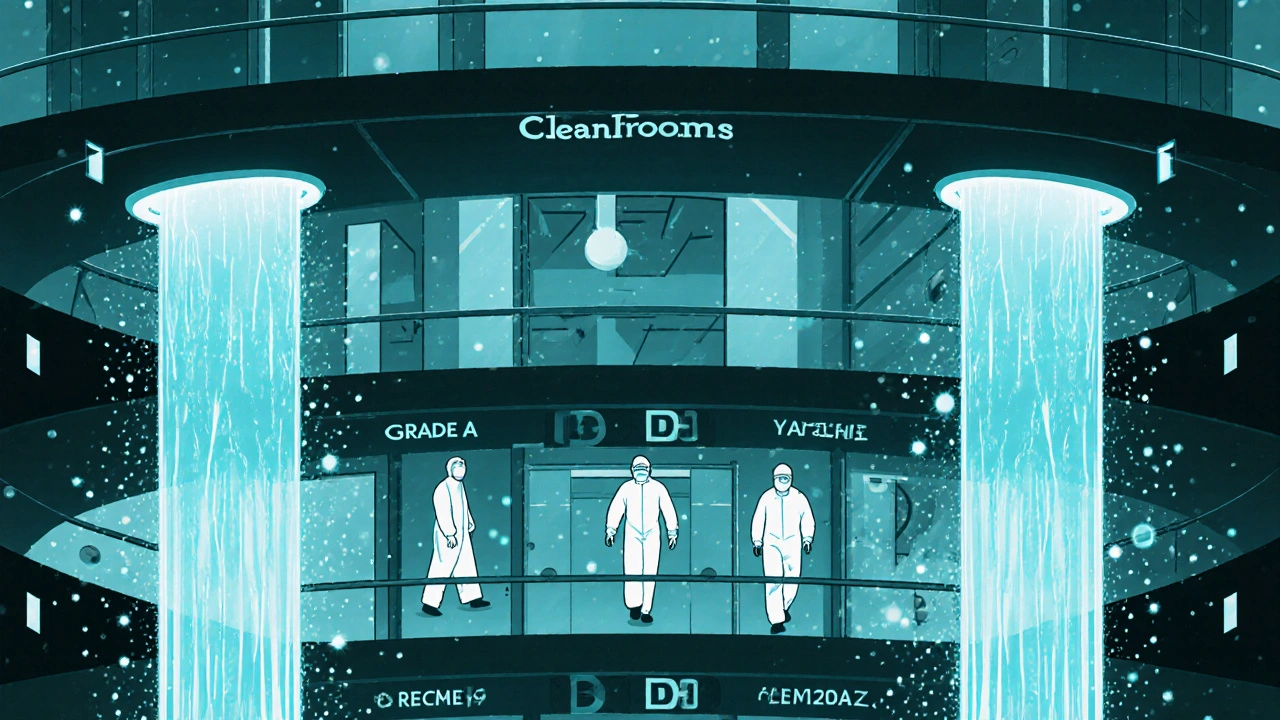

Cleanroom standards ensure generic drugs are safe and effective by controlling airborne particles, microbes, and environmental conditions. Learn how ISO grades, FDA/EU rules, and human factors impact quality - and why compliance isn't optional.

GMP Compliance: What It Means for Your Medications and Why It Matters

When you take a pill, you expect it to work the same way every time—no matter where it was made. That’s where GMP compliance, Good Manufacturing Practices, a set of rules ensuring pharmaceutical products are consistently produced and controlled according to quality standards. Also known as cGMP, it’s the invisible guardrail keeping your medicine safe, effective, and free from contamination. This isn’t just a checklist for factories. It’s the reason your blood pressure pill doesn’t have bits of metal in it, or why your antibiotic doesn’t lose strength before you finish the bottle.

GMP compliance isn’t just about cleaning floors or wearing gloves. It’s about manufacturing changes, any shift in how a drug is made—like switching suppliers, altering equipment, or changing the mixing process. Every single change, no matter how small, has to be documented, tested, and approved. The FDA and global regulators don’t allow guesswork. If a company changes a single ingredient source without approval, that entire batch could be recalled. That’s why regulatory approval, the formal process that validates these changes before they go live is non-negotiable. And when you see headlines about drug shortages or recalls, nine times out of ten, it’s because someone skipped or rushed this step.

Think about pharmaceutical quality, the consistent standard of purity, strength, and performance that every dose must meet. It’s not magic. It’s controlled environments, trained staff, calibrated machines, and audits that happen without warning. The same rules apply whether you’re making a generic blood thinner or a $100,000 cancer drug. That’s why hospital formularies don’t just pick the cheapest option—they pick the one with the cleanest audit trail. And when you report a bad reaction through drug safety, systems like MedWatch that track side effects and link them back to manufacturing batches, investigators trace it all the way back to the production line. GMP compliance turns chaos into control.

You won’t see GMP on the label. You won’t hear your doctor mention it. But if it’s missing, your medicine could be useless—or dangerous. The posts below show you exactly how this invisible system touches everything: from how generics are chosen in hospitals, to why biologics can’t be copied like aspirin, to how a tiny change in a factory can trigger a nationwide recall. These aren’t abstract rules. They’re the reason your meds work—and why they don’t hurt you.