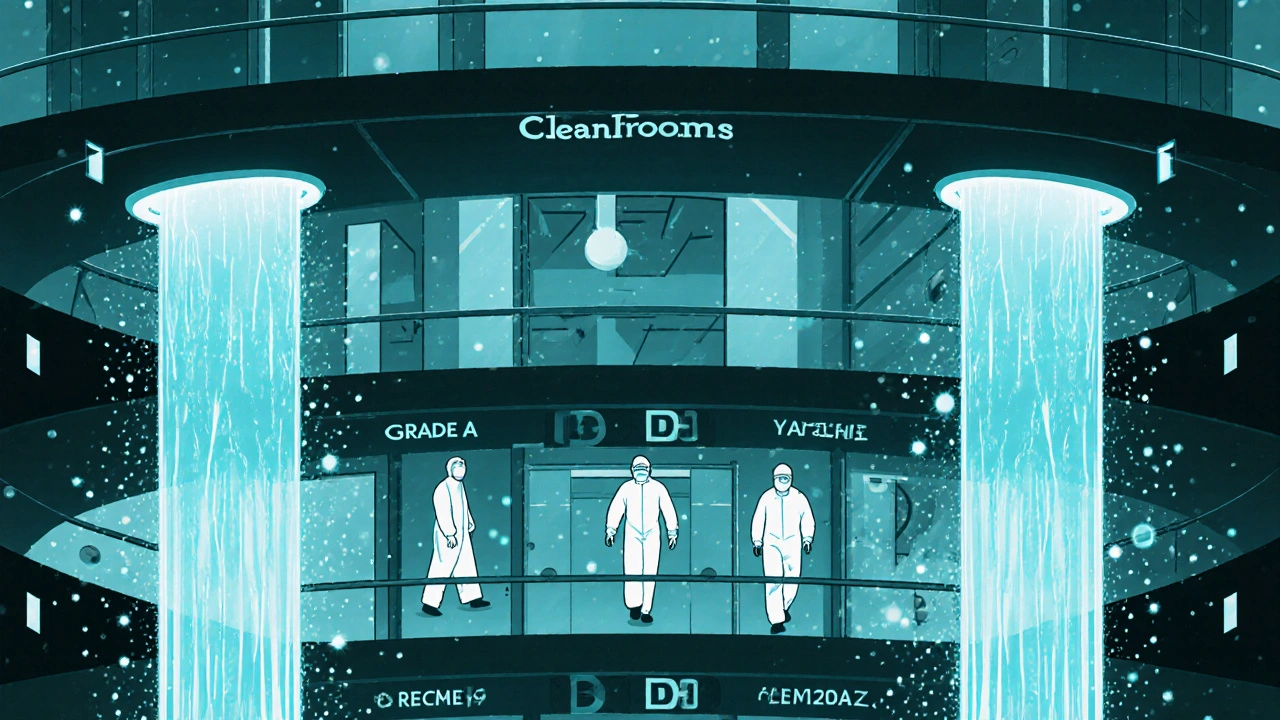

Cleanroom standards ensure generic drugs are safe and effective by controlling airborne particles, microbes, and environmental conditions. Learn how ISO grades, FDA/EU rules, and human factors impact quality - and why compliance isn't optional.

ISO 14644-1: Cleanroom Standards for Pharmaceutical Manufacturing

When it comes to making medicines, even a single particle can ruin a batch. That’s why ISO 14644-1, the international standard defining cleanroom classification by airborne particle concentration. Also known as ISO 14644-1:2015, it’s the rulebook that keeps hospitals, pharmacies, and drug factories safe from contamination. This isn’t just paperwork—it’s what stops bacteria, dust, and human skin cells from ending up in your insulin, antibiotics, or IV fluids.

Under ISO 14644-1, cleanrooms aren’t just "clean"—they’re ranked from Class 1 (ultra-pure) to Class 9 (basic). Each level has exact numbers: how many particles larger than 0.5 microns are allowed per cubic meter of air. For example, a Class 5 cleanroom (common in sterile injectables) lets in no more than 3,520 particles per cubic meter. That’s stricter than a hospital operating room. These numbers aren’t guesses—they’re measured with laser counters, tracked hourly, and audited by regulators like the FDA and EMA. If a factory can’t prove it meets ISO 14644-1, it can’t ship drugs. Period.

The standard doesn’t just cover air. It ties into how people move, what they wear, how equipment is cleaned, and even how air flows into and out of the room. You can’t just slap on a lab coat and call it good. Workers need gowning procedures, airflow must be unidirectional over sensitive areas, and every surface must be non-shedding. This is why companies spend millions on HEPA filters, pressure seals, and training. It’s not optional—it’s the only way to pass inspection.

Related entities like contamination control, the systematic practice of preventing microbial and particulate intrusion in pharmaceutical environments, and cleanroom classification, the system that defines cleanroom performance based on particle counts and airflow are built directly into ISO 14644-1. These aren’t side topics—they’re the core. Even something as simple as a sneeze or a zipper on a gown can trigger a failure if the room doesn’t meet the standard.

What you’ll find in the posts below aren’t abstract theories. These are real-world examples: how manufacturing changes trigger re-certification, why generic drug makers struggle with cleanroom compliance, how FDA inspectors spot violations, and what happens when a biologic drug plant fails an audit. This isn’t about theory—it’s about keeping your medicine safe. And if you work in pharma, or care about what’s in your pill bottle, you need to understand what ISO 14644-1 actually means on the ground.