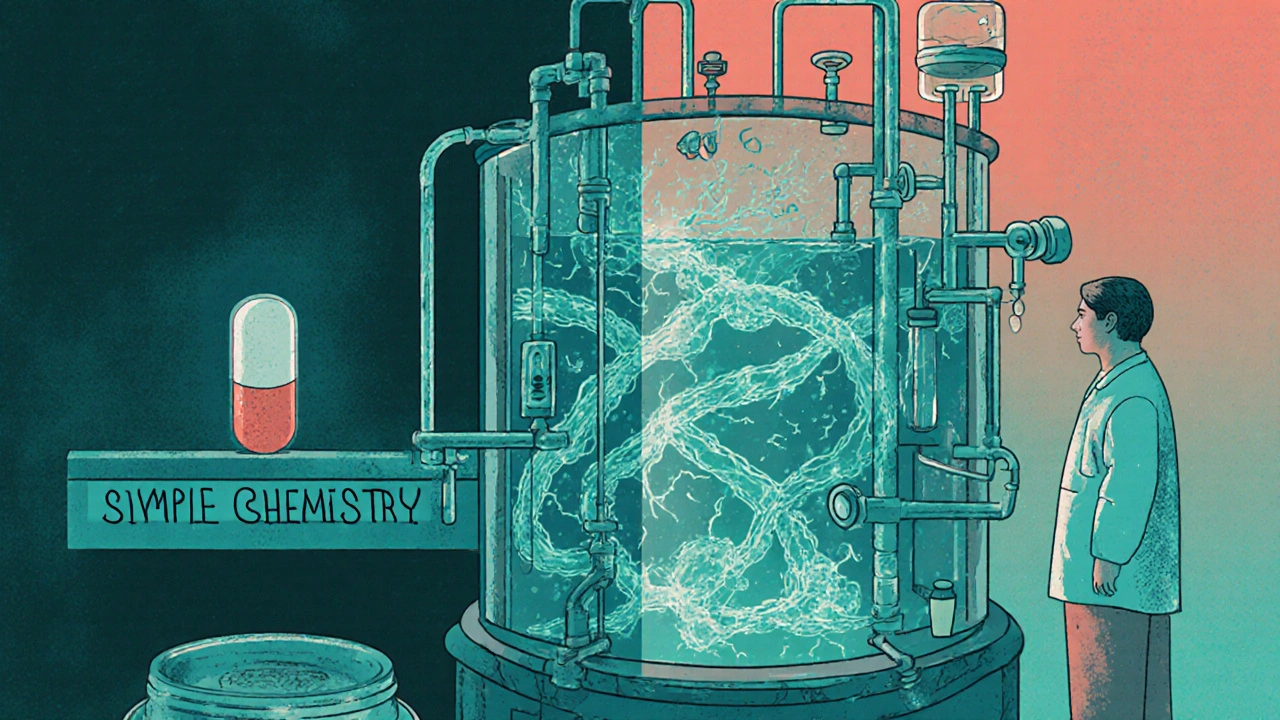

Biologic drugs aren’t like the pills you pick up at the pharmacy. You can’t just swap them out for a cheaper version and expect the same result. That’s because they’re made from living cells - not chemicals. And that tiny difference changes everything.

What Makes Biologics So Different?

Think of a generic pill, like ibuprofen. It’s made by mixing a few chemicals in a lab. Every batch is identical. The molecules are small, simple, and easy to measure. That’s why you can buy a $5 version of a $50 brand-name drug - they’re the same thing.

Now think of a biologic drug like Humira or Ozempic. These aren’t made in a beaker. They’re grown in huge tanks full of living cells - usually hamster or human cells that have been genetically tweaked to produce a specific protein. These proteins are massive. Up to 1,000 times bigger than a typical drug molecule. And because they’re alive, they’re never exactly the same from one batch to the next.

The FDA says this isn’t a flaw - it’s normal. Even the same company can’t make two batches that are 100% identical. Tiny differences in temperature, nutrient levels, or even the air in the room can change how the cells behave. These changes might be invisible to the naked eye, but they can affect how the drug works in your body.

The Manufacturing Process Is Like Baking a Cake… With Living Ingredients

Producing a biologic drug takes 3 to 6 months. Compare that to a generic pill, which can be made in days. Here’s what happens:

- Cell line development: Scientists insert a human gene into a host cell (like a Chinese hamster ovary cell) so it starts making the therapeutic protein.

- Upstream processing: The engineered cells are grown in massive bioreactors - think 10,000-liter tanks - for 10 to 14 days. They need perfect conditions: 36.5°C, pH 7.2, constant oxygen. If the temperature drops by half a degree, the cells might stop producing the protein - or worse, start making something harmful.

- Downstream processing: The protein is pulled out of the cell soup. This involves multiple rounds of purification - protein A chromatography, viral filters, ultrafiltration. Each step removes impurities. But even after all that, the final product isn’t a single molecule. It’s a mix of slightly different versions of the same protein.

- Formulation and packaging: The purified protein is mixed with buffers, stabilizers, and preservatives. Then it’s filled into vials or pens under sterile conditions. Every step is monitored. Every parameter is recorded.

And you can’t skip any step. One mistake - a contaminated filter, a faulty sensor, a power outage - and the entire batch, worth hundreds of thousands of dollars, gets thrown away. Industry surveys show that 10-15% of biologic batches fail during production. That’s why these drugs cost so much.

Why There Are No Exact Copies

Generics copy the chemical formula of a drug. If the active ingredient is aspirin, any lab can make aspirin. But with biologics, the active ingredient isn’t just a molecule - it’s the whole process that made it.

Dr. Susan Dana Jones, a leading expert in biologics, says: “The manufacturing process itself becomes part of the product definition.” That means you can’t just reverse-engineer a biologic. You can’t look at the final product and figure out how to recreate it. The cells, the media, the timing, the equipment - all of it matters.

Even if a company tries to copy a biologic exactly, their cells will behave differently. Their bioreactors will have different airflow. Their filters will have different pore sizes. Their water quality will vary. These tiny differences add up. The result? A product that’s similar - but not the same.

That’s why regulators don’t allow “generic” biologics. Instead, they created a new category: biosimilars.

Biosimilars: Close, But Not the Same

Biosimilars are not generics. They’re highly similar versions of biologic drugs - but they require their own clinical trials to prove they work the same way in patients. The FDA doesn’t require a full new trial for every disease. But they do demand:

- Extensive lab tests comparing the biosimilar’s structure to the original

- Studies showing no difference in how the body absorbs and processes the drug

- At least one clinical trial proving it works just as well for one condition

For example, a biosimilar to Humira had to be tested in patients with rheumatoid arthritis to prove it reduced joint pain just as well as the original. It didn’t need to be tested for psoriasis or Crohn’s disease - unless the manufacturer wanted to claim those uses too.

And even then, biosimilars aren’t interchangeable by default. Pharmacists can’t swap them in without a doctor’s approval - unlike generics. That’s because regulators still worry about subtle differences that might show up over time, especially in patients switching back and forth.

The Cost of Complexity

Building a biologics factory costs between $100 million and $500 million. A single bioreactor can run $10 million. The equipment needs to be sterile, precise, and constantly monitored. Quality control alone makes up 30-40% of the total cost - compared to 5-10% for small molecule drugs.

And the paperwork? Each batch comes with over 10,000 pages of documentation. Every temperature reading. Every pH measurement. Every test result. The FDA requires it all. No exceptions.

That’s why biosimilars still cost tens of thousands of dollars a year - even though they’re cheaper than the original. A biosimilar to Humira might cost $35,000 instead of $70,000. Not $5,000 like a generic. The savings are real, but they’re not massive - because the manufacturing is still incredibly hard.

What’s Changing in Biologics Manufacturing?

The industry is trying to get better. Newer facilities use single-use plastic bags instead of stainless steel tanks. That cuts cleaning time and reduces contamination risk by 60%. But these bags cost 15-20% more.

Some companies are using artificial intelligence to predict how changes in temperature or nutrient levels will affect protein quality. Others are switching to continuous manufacturing - where the process runs nonstop instead of in batches. That could cut production time by 20-30%.

But here’s the catch: even with all this tech, we still can’t fully analyze a biologic. Dr. R. Lou Sherman says current tools can only detect 60-70% of the structural variations in a monoclonal antibody. That means we’re making drugs we don’t fully understand. It’s a leap of faith - and one that regulators are still figuring out how to manage.

What This Means for Patients

If you’re on a biologic drug, you shouldn’t expect a cheap generic version anytime soon. But you might get a biosimilar - and that’s a good thing. Biosimilars are proven safe. They’re often 15-35% cheaper. And they’re expanding access to life-changing treatments for cancer, arthritis, and diabetes.

But don’t assume they’re identical. Your doctor needs to know if you’re switching. Some patients report changes in side effects or effectiveness when moving from the original to a biosimilar. That doesn’t mean the biosimilar is bad - it just means your body might react differently to the tiny variations.

The bottom line: biologics aren’t broken because they’re complex. They’re complex because they work. And that complexity is why we can’t copy them like pills. It’s not a flaw - it’s the price of precision medicine.

Can biosimilars be swapped for the original biologic without a doctor’s approval?

No. Unlike generics, biosimilars are not automatically interchangeable. Pharmacists can’t switch you to a biosimilar without your doctor’s permission. This is because regulators require proof that switching won’t affect safety or effectiveness - and that proof isn’t automatic. Some states allow interchangeability if the FDA has specifically designated a biosimilar as interchangeable, but that’s rare and only applies to a few products.

Why are biologics so expensive if biosimilars exist?

Even though biosimilars are cheaper, they still cost a lot because manufacturing them is incredibly complex. Building the facilities, maintaining sterile conditions, running hundreds of tests, and complying with global regulations adds up. A biosimilar might save you 20-30% compared to the original, but that’s still tens of thousands of dollars a year. The cost isn’t just for the drug - it’s for the science, the equipment, and the expertise behind it.

Are biosimilars as safe as the original biologic?

Yes. Biosimilars must prove they’re as safe and effective as the original through extensive testing - including clinical trials. The FDA and EMA require the same high standards. Millions of patients worldwide have used biosimilars without increased risk. But because biologics are inherently variable, some patients may respond differently when switching. That’s why doctors monitor patients closely after a switch.

Do biosimilars work for all the same conditions as the original drug?

Not always. A biosimilar must prove effectiveness for at least one condition - like rheumatoid arthritis - to get approval. To be approved for other uses - like Crohn’s disease or psoriasis - the manufacturer must provide additional data. Sometimes, they don’t. That means a biosimilar might be approved for one disease but not another, even if the original drug treats both.

Why can’t we just make exact copies of biologics like we do with pills?

Because biologics aren’t made from chemicals - they’re made by living cells. Even if you use the same gene and same process, the cells will behave differently based on tiny changes in environment, equipment, or raw materials. The result is a product with natural, unavoidable variations. You can’t “copy” a living system the way you copy a chemical formula. That’s why regulators call them “highly similar,” not “identical.”

What’s Next?

The future of biologics is moving toward more flexible, smaller manufacturing units - think modular factories that can be set up quickly. That could lower costs and speed up production. But the core truth won’t change: these drugs are too complex to be simple copies. Their power comes from their complexity. And that complexity will always come with a price - not just in money, but in the care, precision, and science it takes to make them.

Sammy Williams

November 21, 2025 at 04:24Man, this post broke it down so well. I never realized how wild it is that biologics are basically grown, not manufactured. It’s like trying to clone a cake recipe where the yeast has a mood every day.

Julia Strothers

November 22, 2025 at 23:13Let me guess - Big Pharma’s hiding the real truth. They don’t want generics because they’re making billions off fear. These ‘biosimilars’? Total scam. The same labs that made the original are probably making these ‘similar’ ones under a different label. Wake up, people - this is just price-gouging with fancy jargon.

Erika Sta. Maria

November 24, 2025 at 10:15Wait… so you’re saying we can’t copy a protein because cells are ‘alive’? That’s not science, that’s mysticism. In India, we’ve been making ayurvedic biologics for centuries without 10,000 pages of paperwork. You think a hamster cell is more sacred than a turmeric root? 😒

Nikhil Purohit

November 24, 2025 at 22:54This is actually super fascinating. I work in biotech and even I didn’t know about the 10-15% batch failure rate. It’s wild how much of this is still black box science - we’re basically trusting machines and cells we don’t fully understand. Kinda humbling, honestly.

Steve Harris

November 26, 2025 at 09:53Great breakdown. One thing I’d add: the real bottleneck isn’t just the tech - it’s regulatory consistency. Different countries have different standards for biosimilars, so even if you make a perfect copy in the US, you might not get approval in the EU without re-testing. That’s why costs stay high globally.

Michael Marrale

November 26, 2025 at 12:25Okay but… what if the government is secretly using AI to clone these drugs in underground labs? I heard the FDA has a secret division that reverse-engineers biologics and sells them to China. That’s why the prices are still high - they’re controlling the supply. 🤫

David vaughan

November 27, 2025 at 05:45I’ve been on Humira for 7 years. Switched to a biosimilar last year. Same side effects, same results. But I had to wait 3 weeks for insurance to approve it. The system is broken, not the science. Biosimilars work. Let people use them. Please.

Cooper Long

November 28, 2025 at 21:21Complexity is not a flaw; it is the essence of biological precision. The notion that life can be reduced to a chemical formula is a reductionist fallacy. Biologics represent the convergence of biology, engineering, and ethics - a triumph of modern medicine, not a failure of manufacturing.

Sheldon Bazinga

November 30, 2025 at 00:11Biologics are just expensive because pharma doesn’t wanna share. They call it ‘complexity’ but it’s just greed wrapped in lab coats. I’ve seen cheaper versions in Mexico - same damn protein. They just don’t have 10k pages of paperwork. #MakeBiologicsCheapAgain