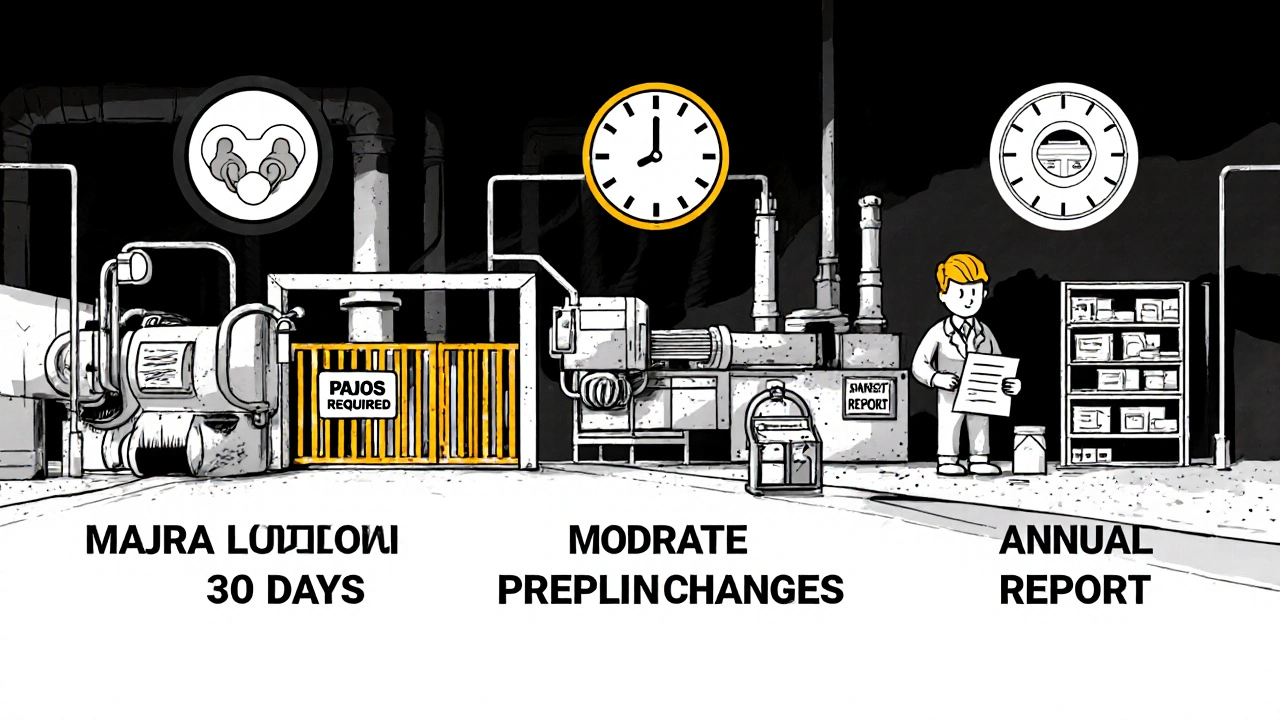

Understand the FDA and global requirements for notifying and approving manufacturing changes in pharmaceutical production. Learn how to classify changes correctly to avoid regulatory violations and ensure product quality.

Manufacturing Changes in Pharmaceuticals: What You Need to Know

When a drug’s manufacturing changes, a shift in how a medicine is made that can affect its safety, performance, or availability. Also known as process modifications, these aren’t just behind-the-scenes updates—they can change how your body responds to the pill in your hand. Even tiny tweaks in the production line—like switching suppliers, adjusting temperature controls, or changing the mix of ingredients—can ripple through the entire system. That’s why the FDA and other regulators treat these changes seriously, even for generics.

Take biologic drugs, complex medicines made from living cells, like Humira or Enbrel. These aren’t simple chemicals you can copy like aspirin. Biosimilars are close copies, but they still need full testing because even small manufacturing changes can alter how they work in your body. That’s why a biosimilar isn’t a generic—it’s a highly similar version that requires its own clinical data. Meanwhile, generic drugs, chemically identical copies of brand-name drugs, also face strict rules when manufacturers change their processes. A switch in the inactive ingredients or the way the tablet is pressed can cause side effects or make the drug less effective for some people. Hospitals and pharmacies track these changes closely because switching generics without warning can lead to unexpected outcomes, like higher hospital readmissions or new side effects.

Manufacturing changes don’t just affect cost or availability—they tie directly into drug safety, how safe a medicine is when used as directed, including risks from production flaws. A 2023 FDA report found that over 40% of drug shortages were linked to production issues, not raw material shortages. That means if your medication suddenly looks different or stops working as well, it might not be your body changing—it’s the factory. That’s why reporting unusual reactions matters. If you notice something off after a refill, file a report with MedWatch. Those reports help regulators catch problems early.

What you’ll find in this collection isn’t just theory. Real cases show how a single manufacturing shift caused confusion in hospitals, why some patients had worse side effects after a generic switch, and how biosimilar approval rules differ between Europe and the U.S. These aren’t abstract policy debates—they’re about the pills you take every day. Whether you’re a patient, caregiver, or healthcare provider, understanding how these changes happen helps you ask the right questions and stay in control of your health.